Band students and students in the CTE (Career Technical Education) program at Weston-McEwen High School have teamed up for an interesting project. They recently used the school’s new 3D printer to manufacture a set of bagpipes.

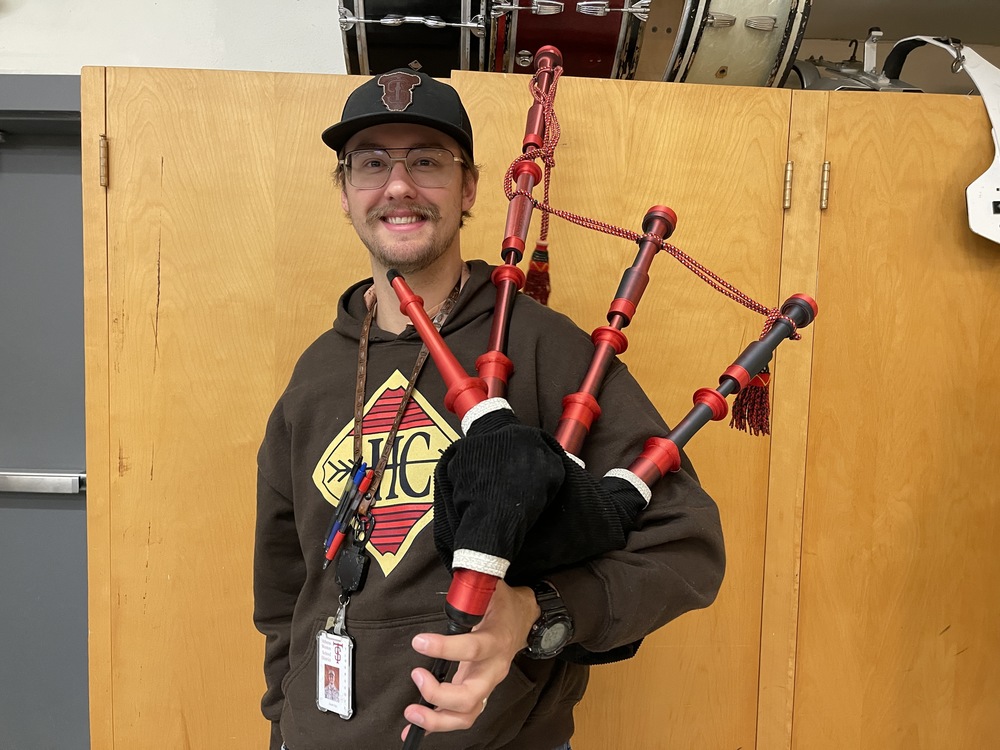

Band Director Jacob Gau said he had seen 3D printed bagpipes before. He talked to CTE Teacher Andrew Griggs and they decided to try making a set. It took about a week for the printing to be done, with some parts taking eight to 11 hours each. Griggs said they had to maneuver and tilt some of the taller pieces to accommodate their printing in the machine. The end result is a set of vibrant, red bagpipes that Gau said sound like any set of bagpipes, which he demonstrated by playing.

So, what’s the benefit? The first is cost. A set of bagpipes usually cost $1,500 to $2,000. Handing those out to every student who may be interested in trying to play is not feasible. The 3-D printed set cost about $400. “That means we could make these bagpipes for students and possibly expand our bagpipe program to maybe the middle school because we would have more instruments,” Gau said.

The manufactured bagpipes also weigh much less than regular bagpipes, which could increase accessibility for students who are smaller in stature and can’t hold the heavier instruments or students with physical challenges.

Griggs said students will now engineer and manufacture some drone reed extenders for the new printed bagpipes, which will help make the new pipes naturally more in tune with the band and make tuning easier.

Way to work together to make beautiful music, TigerScots!